1 of 7

2 of 7

3 of 7

4 of 7

5 of 7

6 of 7

7 of 7

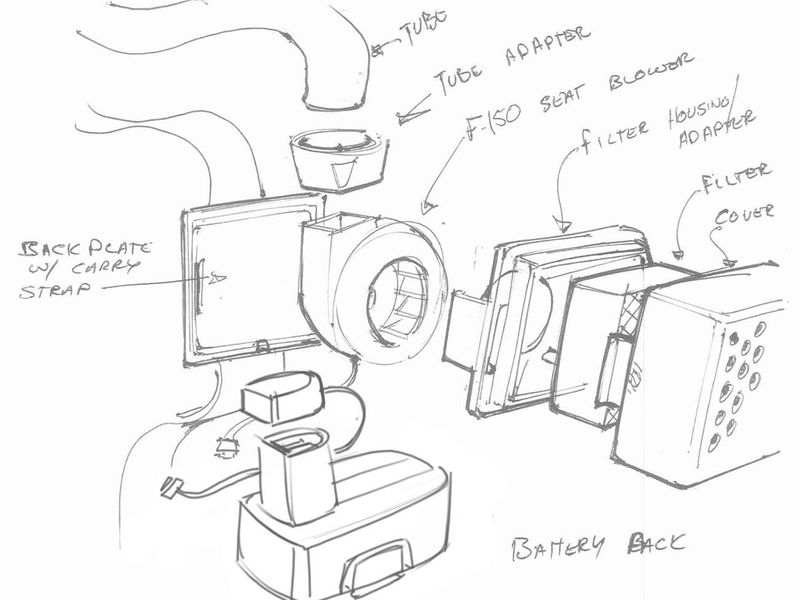

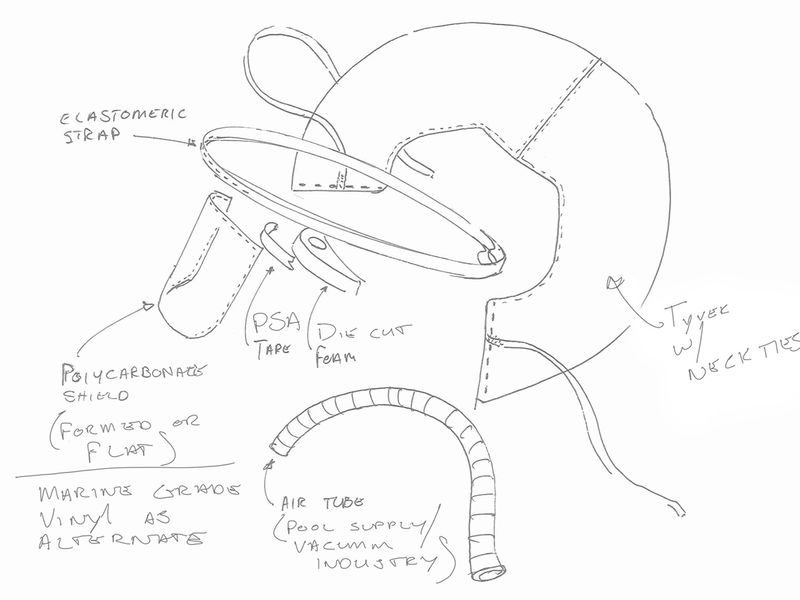

Firms leveraging expertise to meet urgent demand for first responders and health workers